Juli is a renowned and enthusiastic designer of new uniforms. Her consultancy work is defined by strong relationships with her client and manufacturer to ensure the uniform vision is produced.

The Process

”I like to work with what I call a transparent triangle; this includes myself, the manufacturer and the client. This ensures that each sign off is approved by all parties and keeps the integrity of the design from start to finish”

Juli will tailor special packages depending on the scope of work the client requires.

Sustainability

Working with suppliers and manufacturers, Juli oversees the sustainability and ethical production of the uniform. This includes the sustainability and ease of care for the uniform through its lifecycle with her knowledge in fabric technology gained through fabric fairs and manufacturing experience. This can also include advice on how to recycle the old uniforms, such as using them to fill boxing bags or teddies for children's hospitals and suggesting recycled fabrics and trims for the new uniform.

Designing for WestJet , Juli worked closely with Unisync their supplier who created an oeko-tex accredited uniform, this process includes working through the requirements to ensure accreditation is maintained from fabrication to accessories.

Juli has previous experience working with suppliers with the below accreditations for environmental and social responsibility such as: Oeko-tex, BSCI, SEDEX or WRAP standards.

Design Research

Juli works closely with the client to capture their vision. Her work with uniforms builds on her client’s brand heritage and looks forward to the international trends to deliver a uniform package that heightens the brand and leads the market.

Her work looks closely to design for the company’s demographic to ensure inclusivity of the diversity of staff. Presenting concepts that are visually rich and incredibly tied to the wearers of the new uniform.

Juli has attended trade fairs, conventions and fashion weeks around the world, this included an invitation from Brand India (sponsored by the government) to India where she worked with local manufacturers to create an Indian inspired collection, Shanghai Intertextile, Las Vegas WWD Magic trade show, NAUMD uniform convention in Washington, New York and Milan fashion week to name a few.

Garment Quality Assurance

Fabrication - All aspects of the design process are approved by Juli, ensuring efficiency and design vision are achieved. Juli works in person with the manufacturer for design and sample sign off. During the design process, the fabric, accessories and trims are monitored throughout to ensure a professional finish.

Design Execution - Once the first samples are done, these garment “drafts” are presented to the client, then changes are made until the fit is perfect. Juli works the client and supplier to ensure the grading and sizing is within guidelines and is translated correctly suiting the client's demographic and needs. This is done to ensure fit, and cut is maintained for all sizes.

Wear trial period - If time allows it’s preferable to have a ‘wear trial period’. A select number of staff wear samples to do their daily duties at work for a few weeks. After wear trial the staff report back to the design committee and Juli with any problems, this can be anything from fabric to fit. This gives us time to make any changes before production starts.

Staff Engagement

Staff engagement with Juli starts right at the beginning of the design process with focus groups and site visits and continues as required throughout the process, this increases staff morale and confirms that their feedback is considered and important.

During the design process it’s essential to speak to the staff and discover their needs, what they like about the current uniform and what their expectations are for the new uniform. All this is taken into consideration when designing each style.

During the transition period for the new uniforms, it is beneficial for Juli to speak with staff to ensure the uniform change is smooth and to share the vision and journey.

Staff feedback continues to be important even after the launch and if required further enhancements are made.

Factory Visits

If required Juli regularly visits the factories involved in the manufacturing of the uniforms. Whilst there she can share her vision and work directly with the pattern masters to create the perfect fit.

Factory visits are always recommended during the sampling phase to ensure all the garments are made correctly and efficiently. Juli does quality checks on everything from the fabric to the accessories, ensuring ethical production of the uniform line.

Since 2001 Juli has visited factories all over the world from China, Fiji, India, Barbados and America.

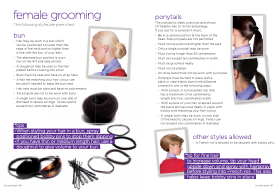

Grooming Guide

Juli Grbac will work with the client to develop all the wear recommendations for the new uniform. This guarantees that uniform presentation is consistent and highlight the employee voice in the final designs. Additionally, the guide showcases correct wear of uniform to follow WH&S standards.

If required Juli and the ’Grooming Committee’ will have regular meetings throughout the process and involve staff from all areas of the company in feed back sessions.

All decisions from the colour of the nail polish the females wear, to the way the men wear their jackets done up will be made prior to launch.

Media Launches and Press

During the design process and launch, Juli has been involved with promotional activities including media interviews, TV commercials, magazine publications and in-flight entertainment.

Uniform Refresh

After a few years of wear, extra pieces can be added or refreshed, Juli is available to come back as a consultant during the time the uniform is worn to work on updates required.

This is more cost effective than another uniform redesign and maintains consistency in brand image.

A refresh always increases staff morale through seeking their involvement and ideas and having more items available to them.

Juli is still working with Virgin Australia 13 years later, working on supplier changes, uniform updates, fabric improvements and refresh suggestions.